Industrial machinery

Dosing machinery

Movacolor is the first choice of plastics producers worldwide that strive for excellence in injection molding or extrusion. With three decades of experience with dosing systems, we don’t simply meet our customers’ demands for stable production, high quality, improved efficiency and lower costs & scrap volumes - we exceed them because of our constant innovations in dosing technology.

Volumetric dosing systems for injection molding and extrusion

Movacolor develops and markets volumetric dosing systems with a unique ultra-precise dosing cylinder for extrusion and injection molding. Our volumetric dosing systems are installed in factories all over the world and can operate under almost any conditions.

Volumetric dosing entrance model: MC12 Economy

The volumetric dosing system MC12 Economy is the entrance model of Movacolor and well sold for injection molding applications. The MC12 Economy is our most economically priced dosing system and fits perfectly for coloring PET, caps and closures, toys and other applications in the plastics processing industry.

Volumetric dosing synchronization with the MC18 Synchronic

The volumetric dosing system MC18 Synchronic is mostly used in the extrusion industry. The MC18 Synchronic is equipped with a special feature that it adjusts automatically to the extruder speed. Plastic producers who opt for an automatic hopper loader to fill the hopper with masterbatch, powder or regrind choose our volumetric dosing system MC18 Synchronic.

Volumetric dosing calibration with the MC30 Auto Calibrate

The volumetric dosing system MC30 Auto Calibrate is equipped with an automatic material calibration function. Further extra features are:

Volumetric dosing entrance model: MC12 Economy

The volumetric dosing system MC12 Economy is the entrance model of Movacolor and well sold for injection molding applications. The MC12 Economy is our most economically priced dosing system and fits perfectly for coloring PET, caps and closures, toys and other applications in the plastics processing industry.

Volumetric dosing synchronization with the MC18 Synchronic

The volumetric dosing system MC18 Synchronic is mostly used in the extrusion industry. The MC18 Synchronic is equipped with a special feature that it adjusts automatically to the extruder speed. Plastic producers who opt for an automatic hopper loader to fill the hopper with masterbatch, powder or regrind choose our volumetric dosing system MC18 Synchronic.

Volumetric dosing calibration with the MC30 Auto Calibrate

The volumetric dosing system MC30 Auto Calibrate is equipped with an automatic material calibration function. Further extra features are:

- Accurate feeding through dosing cylinder

- Stepper motor speed starting from 0.1 up to 200 rpm

- Manual adjustment

- Capacity 0.07-180 kg/h, measured with normal granular masterbatch 0.8 kg/dm3

- Automatic recipes storage function

- The menu-guided control has a graphic LCD display with backlight

- A warning and alarm output and an integrated hopper loader control are also part of the MC30

- This volumetric feeder is suitable for both injection molding and extrusion

Easy-to-operate gravimetric feeders to handle any kind of material

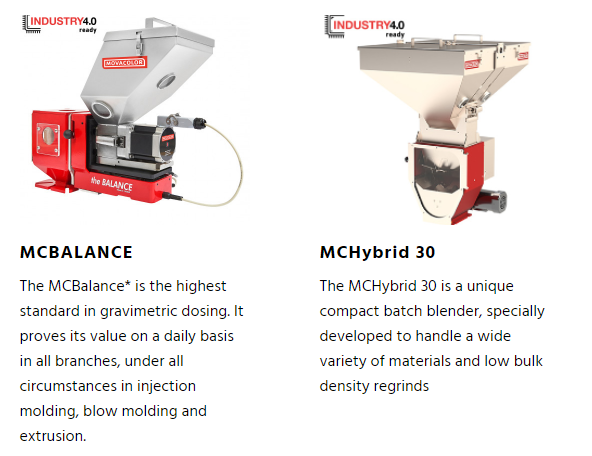

Movacolor introduced as one of the first in the world their patented gravimetric dosing technology with the development of the highly accurate MCBalance. This dosing unit is the highest standard in gravimetric dosing and can be used by plastic producers on a daily basis in extrusion, injection molding and blow molding. The highly accurate Movacolor gravimetric dosing technology is based on a loss-in-weight weighing system and a dosing cylinder which doses in a straight line without any pulsations.

The gravimetric feeders of Movacolor are equipped with a Movacolor touch screen controller and MCSmart software, which gives you full control over your extrusion, injection molding or blow molding process. The Movacolor touch screen controllers are designed in a way every operator in the plastics industry can work with it, with initial start-up of your injection molding machine or extruder taking no time at all.

To broaden the successful gravimetric feeder product line, Movacolor focused on the difficulties plastics producers face when dosing hard to handle materials like regrind, powder or liquid. Therefor the engineers of Movacolor developed the MCTwin, MCHybrid 30R-series and MCHigh Output 2500R, that can easily handle regrind. Next to that the MCPowder, MCPowder High Output and MCLiquid can easily dose materials like powders and liquids.

Modular gravimetric dosing systems for specific plastic production processes

For higher capacities Movacolor has developed the MCHigh Output and MCHigh Output 2500R. These gravimetric dosing systems can dose from 50 kilogram per hour up to 1,200 kilogram per hour, without making any concessions to accuracy. The MCHigh Output 2500R has especially been developed to handle low bulk density regrind like PET-flakes, which can be reused into the production process up to 75%.

Movacolor also offers gravimetric blenders in their product range, which are unique in the world of dosing. The innovative gravimetric blenders MCHybrid 30 and MCHybrid 200 are developed with a special dosing principle, which combines two technologies in one system: batch-blending and in-line gravimetric dosing. The Movacolor gravimetric blender product line also offers a regrind-version: the MCHybrid 30R-series.

All gravimetric dosing systems of Movacolor are modular. This means plastic producers using an injection molding machine, blow molding machine or extruder can use a Movacolor dosing unit that has been created to client specification. This particular dosing unit is perfectly suited to any production type in extrusion, injection molding or blow molding applications. Setting up or making dosing systems ready for operation is extremely simple and can be handled by anyone working in the production

Dosing software that offers complete control over production process

With the highly intelligent dosing software of Movacolor you will be able to fully control your injection molding or extrusion process. Our software product line consist of MCSmart dosing software and MCLine Control. All gravimetric and optometric dosing systems can be equipped with Movacolor dosing software. All Movacolor software applications are developed in-house by our own professional software engineers.

Easy-to-operate gravimetric feeders to handle any kind of material

Movacolor introduced as one of the first in the world their patented gravimetric dosing technology with the development of the highly accurate MCBalance. This dosing unit is the highest standard in gravimetric dosing and can be used by plastic producers on a daily basis in extrusion, injection molding and blow molding. The highly accurate Movacolor gravimetric dosing technology is based on a loss-in-weight weighing system and a dosing cylinder which doses in a straight line without any pulsations.

The gravimetric feeders of Movacolor are equipped with a Movacolor touch screen controller and MCSmart software, which gives you full control over your extrusion, injection molding or blow molding process. The Movacolor touch screen controllers are designed in a way every operator in the plastics industry can work with it, with initial start-up of your injection molding machine or extruder taking no time at all.

To broaden the successful gravimetric feeder product line, Movacolor focused on the difficulties plastics producers face when dosing hard to handle materials like regrind, powder or liquid. Therefor the engineers of Movacolor developed the MCTwin, MCHybrid 30R-series and MCHigh Output 2500R, that can easily handle regrind. Next to that the MCPowder, MCPowder High Output and MCLiquid can easily dose materials like powders and liquids.

Modular gravimetric dosing systems for specific plastic production processes

For higher capacities Movacolor has developed the MCHigh Output and MCHigh Output 2500R. These gravimetric dosing systems can dose from 50 kilogram per hour up to 1,200 kilogram per hour, without making any concessions to accuracy. The MCHigh Output 2500R has especially been developed to handle low bulk density regrind like PET-flakes, which can be reused into the production process up to 75%.

Movacolor also offers gravimetric blenders in their product range, which are unique in the world of dosing. The innovative gravimetric blenders MCHybrid 30 and MCHybrid 200 are developed with a special dosing principle, which combines two technologies in one system: batch-blending and in-line gravimetric dosing. The Movacolor gravimetric blender product line also offers a regrind-version: the MCHybrid 30R-series.

All gravimetric dosing systems of Movacolor are modular. This means plastic producers using an injection molding machine, blow molding machine or extruder can use a Movacolor dosing unit that has been created to client specification. This particular dosing unit is perfectly suited to any production type in extrusion, injection molding or blow molding applications. Setting up or making dosing systems ready for operation is extremely simple and can be handled by anyone working in the production

Dosing software that offers complete control over production process

With the highly intelligent dosing software of Movacolor you will be able to fully control your injection molding or extrusion process. Our software product line consist of MCSmart dosing software and MCLine Control. All gravimetric and optometric dosing systems can be equipped with Movacolor dosing software. All Movacolor software applications are developed in-house by our own professional software engineers.

Dosing software for monitoring, quality control and material management 24/7

Next to the development of highly accurate dosing systems, Movacolor also developed the innovative MCSmart dosing software. MCSmart dosing software combined with one or more Movacolor touch screen controllers transforms your gravimetric feeder or optometric feeder into a highly intelligent self-regulating dosing system.

Once connected to your gravimetric or optometric feeder, the MCSmart dosing software constantly monitors your injection molding or extrusion process and you will get full control over the quality of your end product and the management of your raw materials. MCSmart dosing software of Movacolor is based on a SQL database for 24/7 of data collection. Data can be retrieved at any time, even after months.

Software installation and special features MCSmart

MCSmart dosing software can be installed as a standalone application on a computer or as a server application. The connection of the MCSmart dosing software is established via a standard LAN network. The MCSmart dosing software database can be accessed by multiple authorized desktop users.

There are several features available in MCSmart dosing software. All features can be accessed based on the login level settings of the user. This prevents unauthorized use of the MCSmart dosing software database. The MCSmart software database has an unlimited function for generating reports on material consumption and alarm overview reports.

All recipes for injection molding and extrusion applications can be created and managed in MCSmart dosing software. The recipes are synchronized with separate units and can be activated locally or remotely. This prevents any operating errors. With the remote control function of the MCSmart dosing software you can duplicate the touch screen on your computer and perform all operations as if you were standing in front of the device.

Software set-up to get full control over your extrusion lines

In the plastics industry increasing material prices and the demand for high quality end products are high on the agenda. This makes it more than ever important to get full control over your extrusion process. The MCLine Control of Movacolor is the solution. It gives you complete control over your extrusion process.

The MCLine Control of Movacolor works with the gravimetric feeder MCWeight in combination with MCSmart dosing software. The MCWeight measures the throughput in the capacity range and the easy to use Movacolor touch screen controller can be connected directly to the extrusion line.

Need advice about what our dosing software can do for you to improve the performance of your injection molding machine or extruder? Please contact our dosing specialists.

Dosing software for monitoring, quality control and material management 24/7

Next to the development of highly accurate dosing systems, Movacolor also developed the innovative MCSmart dosing software. MCSmart dosing software combined with one or more Movacolor touch screen controllers transforms your gravimetric feeder or optometric feeder into a highly intelligent self-regulating dosing system.

Once connected to your gravimetric or optometric feeder, the MCSmart dosing software constantly monitors your injection molding or extrusion process and you will get full control over the quality of your end product and the management of your raw materials. MCSmart dosing software of Movacolor is based on a SQL database for 24/7 of data collection. Data can be retrieved at any time, even after months.

Software installation and special features MCSmart

MCSmart dosing software can be installed as a standalone application on a computer or as a server application. The connection of the MCSmart dosing software is established via a standard LAN network. The MCSmart dosing software database can be accessed by multiple authorized desktop users.

There are several features available in MCSmart dosing software. All features can be accessed based on the login level settings of the user. This prevents unauthorized use of the MCSmart dosing software database. The MCSmart software database has an unlimited function for generating reports on material consumption and alarm overview reports.

All recipes for injection molding and extrusion applications can be created and managed in MCSmart dosing software. The recipes are synchronized with separate units and can be activated locally or remotely. This prevents any operating errors. With the remote control function of the MCSmart dosing software you can duplicate the touch screen on your computer and perform all operations as if you were standing in front of the device.

Software set-up to get full control over your extrusion lines

In the plastics industry increasing material prices and the demand for high quality end products are high on the agenda. This makes it more than ever important to get full control over your extrusion process. The MCLine Control of Movacolor is the solution. It gives you complete control over your extrusion process.

The MCLine Control of Movacolor works with the gravimetric feeder MCWeight in combination with MCSmart dosing software. The MCWeight measures the throughput in the capacity range and the easy to use Movacolor touch screen controller can be connected directly to the extrusion line.

Need advice about what our dosing software can do for you to improve the performance of your injection molding machine or extruder? Please contact our dosing specialists.